3D Printer, FDM 3D Printer with heated bed, 8G SD Card, Filament Runout

3D Printer, FDM 3D Printer with heated bed, 8G SD Card, Filament Runout Detection, Large Build Volume 8.7×8.7×9.8 inch for 1.75mm PLA/ABS Filament, Auto Leveling, Resume Print, 10m PLA Filame

- .

- .

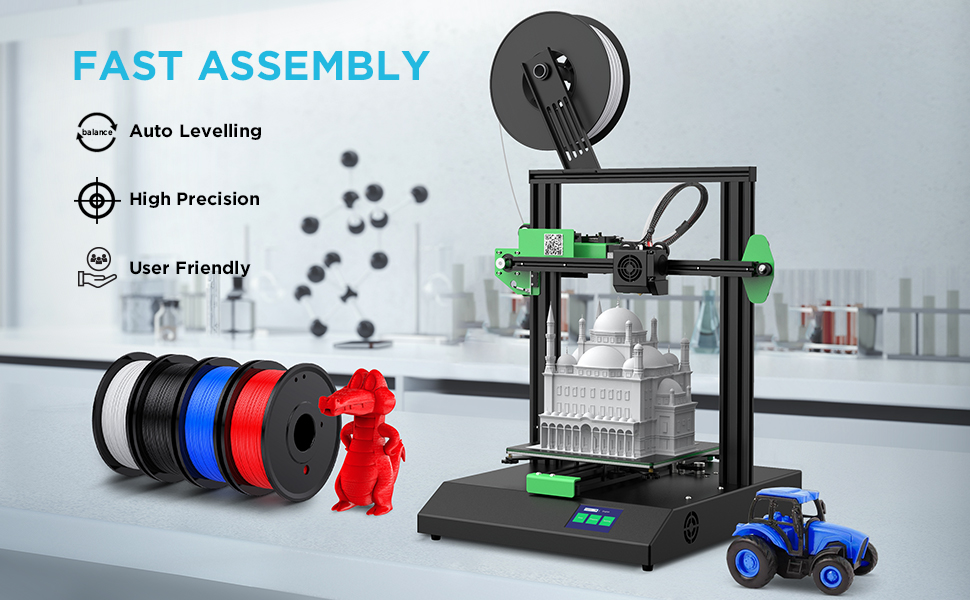

- Fast heating: The heating bed of the 3D printer is heated evenly, only 5 minutes, the temperature of the heating bed can reach the desired temperature, which saves you a lot of time.In addition, there is a coating on the surface of the glass.The coating can better prevent damage to the printing bed.

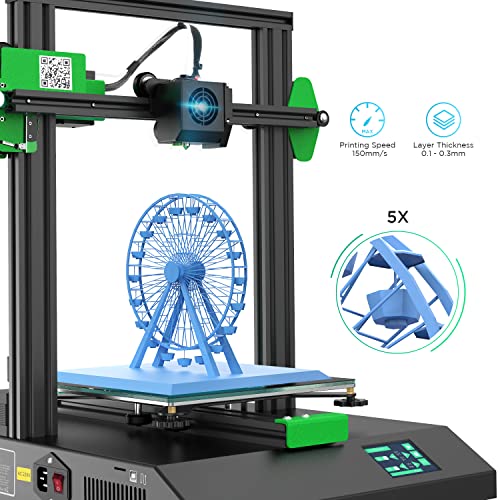

- Large printing area: With its printing size of the printer of 220 x 220 x 250mm, it offers the user a large building volume. With an easy-to-use and clearly designed touch screen, you can control the machine in one interface. Moreover, you can choose the right language according to your requirements.

- High quality printing: This 3D printer comes with a glass plate on a conventional heated bed, which largely solves the problem of curvature, ensuring extremely high print quality. The rigid metal frame improves the stability of the machine, optimising accuracy and ensuring you get perfect layer lines every time.

- Professional Extruder: The large 3d printer has double wheel extrusion structure, which is a new type of gapless connection structure design. It will greatly reduces the risk of clogged nozzle and bad extrution, and it is suitable for a variety of different printing materials.

- Easy to Operate: Each axis of the ET4 3D printer is made of wear-resistant aluminum profile, which offers the quieter 3D printing, so you don’t have to worry about annoying noise that may be generated during printing.

| SKU: | B09T6W8H1H |

| Dimensions: | 44 x 42 x 48 cm; 7 Kilograms |

| Manufacture: | Popozono |

| Origin: | China |

Product Description

Tipps:

1. After the lack of material in the middle of printing, the filament is stuck between the filament detector and the extruder. How to solve the problem?

Cut the filaments from the filament detector to the extruder with pliers, and then click [Filament-Load].

2. Why is it easy to warp edge when printing?

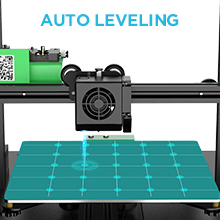

a. Warping edge is usually due to incorrect setting of leveling compensation parameters. When printing the first layer, the distance between the nozzle and the printing platform is relatively long, resulting in printing cannot adhere to the heating bed.

b. Contaminants such as grease, dust, etc. should be wiped with alcohol after the temperature of the heating bed drops to normal temperature.

c. The printing platform is too smooth. Please cover the printing platform with a masking paper, or a special PC film for 3D printing, or stick the platform with solid glue.

d. The shrinkage rate of each filament is different. The filament with high shrinkage rate (such as ABS) is easy to warp edges. PLA material is recommended.

e. During a print, the air-conditioner blows against the model, which can easily cause warping. The ideal condition is to prevent the air flow near the printer or to find ways to keep warm.

3. After automatic leveling, no filament feed when printing, and friction sound between nozzle and hotbed.

The leveling compensation is too small. Click [+] to flatten the compensation, and test it many times until it is appropriate. Leveling compensation can be reset at any time when the machine is not in use, and can be set multiple times if necessary.

4. After installing the automatic leveling sensor and clicking [automatic leveling], the Z axis has been falling, and the nozzle bumps into the printing platform without stopping.

a. Check whether the leveling sensor plug is properly inserted (regardless of positive or negative).

b. Change a new leveling sensor.

5. The X or Y axis can only run in one direction.

Check if the limit switch is stuck or the leaf spring is functioning properly, please recover it if needed.

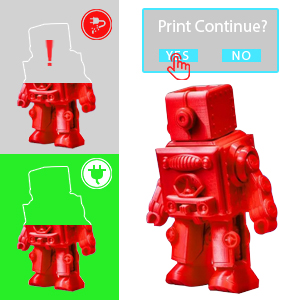

6. Why does it stop automatically in the process of printing?

a. In the online printing process, computer shutdown, computer crash, bad USB connection and other phenomena will cause print termination.

b. Slice files are interrupted when they are saved to TF cards, resulting in missing files.

c. Aging of TF Card.

d. Check for power failure, material shortage, etc.

7. Why do some models print the wrong layer?

a. It is possible that the belt is too loose. Check and tighten the belt.

b. Check whether the screws of the wheel in the wrong direction are tightened.

c. Check the printing speed on the slicing software, and it is recommended that between 30~60mm/s.

d. Check whether the radiator on the right side of the chassis is working properly. Abnormal heat dissipation will cause motor drive chip overheating, which will cause printing the wrong layer.

e. Replace the model.

8. The extruder cannot extrude filaments, and there is no prompt message on the screen display.

a. Check whether the main cable is inserted properly and the motor line of E axis is inserted properly

b. Check that whether the preheating temperature is correct. The preheating temperature is generally 200℃.