The Stove Wizard DIY Pizza Oven Refractory Fire Clay Powdered for Furnaces Kilns

The Stove Wizard DIY Pizza Oven Refractory Fire Clay Powdered for Furnaces Kilns Tandoori Oven 25kg Bag

- Refractory Raw Material: Fire clay is highly regarded as a refractory raw material. Its ability to withstand high temperatures makes it valuable for lining furnaces and other heat-intensive environments.

- Applications: Glass Melting Furnaces: Fire clay is used in glass melting furnaces, where extreme heat is required to melt glass. Boiler Furnaces: It’s also employed in boiler furnaces, ensuring durability and resistance to heat. Chimney Linings: Fire clay lines chimneys, protecting them from the intense heat generated during combustion. Pottery Kilns: Pottery kilns benefit from fire clay linings, allowing them to reach high firing temperatures.

- Blast Furnaces: Blast furnaces, used in metal production, utilize fire clay for their linings. Reheating Furnaces: These furnaces, common in steel mills, rely on fire clay for insulation. Outdoor Pizza Ovens: Fire clay is an excellent choice for constructing pizza ovens, where temperatures need to exceed 600°C (1112°F) for that perfect crust.

- High Temperature Resistance: Fire clay’s fusion point exceeds 1,600°C (2,910°F), making it ideal for applications where extreme heat is involved.

- Cost-Effective Alternative to Refractory Cement: While refractory cement can be expensive, powdered fire clay offers a more budget-friendly option without compromising performance.

- Gap Filler and Leveller: Before laying bricks in kilns or ovens, fire clay serves as an excellent gap filler or leveller. It ensures a smooth and even surface for brickwork

- DIY Refractory Projects: As you mentioned, this material can be used to create your own refractory components, such as pizza oven floors or furnace linings.

1. Refractory Raw Material: Fire clay is highly regarded as a refractory raw material. Its ability to withstand high temperatures makes it valuable for lining furnaces and other heat-intensive environments. 2. Applications: Glass Melting Furnaces: Fire clay is used in glass melting furnaces, where extreme heat is required to melt glass. Boiler Furnaces: It’s also employed in boiler furnaces, ensuring durability and resistance to heat. Chimney Linings: Fire clay lines chimneys, protecting them from the intense heat generated during combustion. Pottery Kilns: Pottery kilns benefit from fire clay linings, allowing them to reach high firing temperatures. Blast Furnaces: Blast furnaces, used in metal production, utilize fire clay for their linings. Reheating Furnaces: These furnaces, common in steel mills, rely on fire clay for insulation. Outdoor Pizza Ovens: Fire clay is an excellent choice for constructing pizza ovens, where temperatures need to exceed 600°C (1112°F) for that perfect crust. 3. High Temperature Resistance: Fire clay’s fusion point exceeds 1,600°C (2,910°F), making it ideal for applications where extreme heat is involved. 4. Cost-Effective Alternative to Refractory Cement: While refractory cement can be expensive, powdered fire clay offers a more budget-friendly option without compromising performance. 5. Gap Filler and Leveller: Before laying bricks in kilns or ovens, fire clay serves as an excellent gap filler or leveller. It ensures a smooth and even surface for brickwork. 6. DIY Refractory Projects: As you mentioned, this material can be used to create your own refractory components, such as pizza oven floors or furnace linings.

| SKU: | B0D62MXBL1 |

| Dimensions: | 50 x 40 x 25 cm |

| Brand: | The Stove Wizard |

| Model: | 25kg bag Powdered Fire Clay |

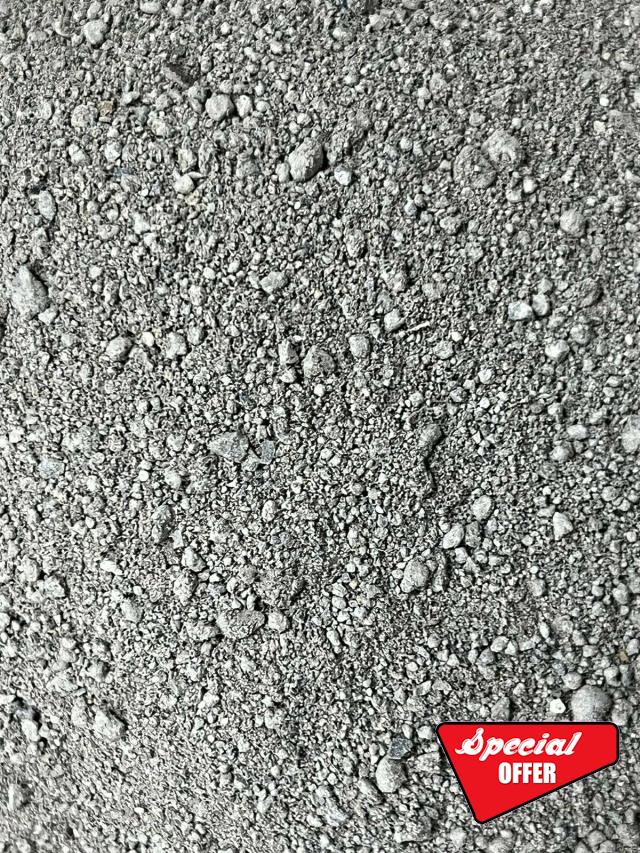

| Colour: | grey |